DTF – The Process Explained

Step by Step with The Craft Express Elite DTF Printer

For those unfamiliar with the term, DTF (or Direct to Film) is a process for producing transfers that can be applied to the broadest possible range of fabrics available.

The scope here is enormous – everyday garments can be decorated, but so too can heavy duty workwear, as well as lightweight sports and performance wear.

The process offers simple production of transfers with no weeding or production of masks, but delivering long lasting results that stretch and wash in a way that compare to screen printing or sublimation.

Transfers are printed onto film, with the colour being laid down, and covered with a base of white ink.

This printed film is then covered with a translucent ‘hot melt powder’, which is then cured by heat (typically oven or heat press) at around 120°C for 5 minutes. The result is a very thin, incredibly stretchy transfer that can be applied with a firm pressure at a temperature of 150°C and a very short time of just 20 seconds.

This solution offers a compelling package – low startup costs, a compact desktop form factor and the flexibility to produce one off and short run DTF transfers. Capable of printing roll or sheet fed media up to 30cm width, this compact system also offers in built white recirculation to assist with maintenance.

This makes it perfect for those who want to avoid the additional costs, minimum order quantities and turnaround times of outsourced production.

Whether you are incorporating DTF into your existing business workflow or starting from scratch, a DTF based printing business requires an initial investment in equipment and materials, but it can be a lucrative venture with the right skills and marketing efforts. Continuously learning and improving your skills will help you stay competitive in the market.

The team here at Nova Chrome UK have created a guide to help you with the essential steps to take when using the Craft Express Elite A3 DTF Printer, Heat Press, and Curing Oven of choice in your DTF workflow.

THE DTF PROCESS – Our Step By Step Guide

1 : PREPARE OR DESIGN YOUR ARTWORK

Start by creating or selecting your supplied design in your preferred graphic software. Ensure the design is in a high-resolution format for the best print quality.

- Export/Save your design to a supported file format – preferably a transparent .PNG in high resolution 300dpi, in the sRGB colour space.

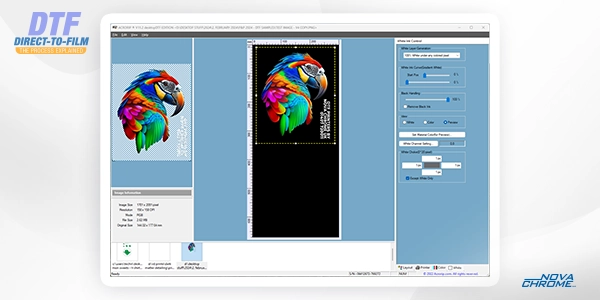

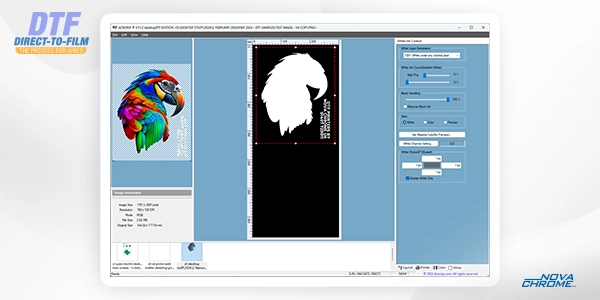

- Open your exported artwork file in the supplied AcroRIP software. This software enables your Craft Express Elite DTF Printer to process and print your artwork.

2 : PREPARE YOUR PRINTER

- Ensure the printer is loaded with either a DTF sheet, or a roll of DTF film set to feed through with the print side facing up.

- Check that the Inks are correct and within the required levels.

- Perform a nozzle check and / or head clean as required. This should be done daily, even if not actively printing.

3 : PRINT YOUR DESIGN

- Print your design onto the film using the supplied Acrorip software.

- The printer will apply a layer of colour ink followed by white ink to ensure vibrant and opaque prints.

- Check the print quality is satisfactory for your specific usage requirements before continuing to the next step.

4 : APPLY HOTMELT POWDER TO THE PRINTED DESIGN

Once the printer image has been printed, it is necessary to apply an even coating of Hotmelt DTF powder to the print in preparation for curing.

- Using a tray, set the newly printed image down with the print side facing up.

- Apply a liberal amount of DTF Hotmelt powder to the printed image.

- Shake any excess powder into the tray, whilst ensuring that the artwork is completely covered in the powder.

- Gently flick the film to remove any excess powder.

- Whilst it’s possible to reuse / recycle excess powder, it’s important that this is syphoned into a separate container for storage, to minimise the risk of hairs or other contaminants mixing with fresh powder.

5 : CURE THE HOTMELT POWDER

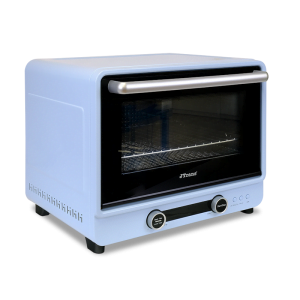

With your printed artwork now covered evenly with DTF Hotmelt Powder it is now time to cure the powder and artwork. For consistent results and a reliable workflow, we suggest the use of the Craft Express iSmart Oven – the multiple shelves allow for multiple sheets to be cured at the same time.

- Carefully place the powdered DTF film into the Craft Express Curing Oven.

- Cure the DTF film in the oven at a temperature of 120°C for 5 minutes.

- When the hotmelt powder develops an orange-peel effect it has melted correctly onto the artwork.

- This will form an adhesive base when transfering the design to the garment using a flat bed heat press.

6 : PREPARE THE GARMENT

- Place your garment on the heat press bed/platen.

- Ensure the garment is positioned correctly to receive the prepared DTF printed artwork.

- Check for and remove any loose fibres, or debris from the garment print area using a lint roller.

- Place a sheet of thermal buttress paper onto the pressing area of the garment.

- Pre-press the garment to remove any moisture and to smooth out any creases.

7 : PRESS THE ARTWORK TO THE GARMENT

In this step we will use a flat bed heat press to transfer the DTF printed artwork to the garment.

Our heat pressing guides are based on the use of our recommended ink, film and hotmelt powder.

- Position the prepared DTF film as required onto the pre-pressed area of the garment.

- Place a sheet of thermal buttress paper on top of the DTF Sheet/Garment to minimise risk of damaging the garment.

- We recommend pressing the prepared DTF artwork onto the garment at 150°C for 20 Seconds.

8 : COOLDOWN AND PEEL

Once the garment and artwork have been pressed together it is time to put the garment aside to cooldown. Carefully remove the pressed garment from the heatpress.

Lay the garment down onto a flat surface and allow to cool. Once cooled, carefully peel the DTF film from the garment to reveal your freshly pressed artwork!

- After pressing, remove the garment from the heat press and let it cool completely.

- Once cooled, carefully peel the DTF film from the garment to reveal your freshly pressed artwork!

9 : YOUR GARMENT IS READY!

Once the garment has been pressed and the DTF film removed your garment is ready!

- Check the final printed design meets your quality standards.

- Check for print defects or any other issues.

- Check colours are representitive of your artwork correctly.

- Optionally continue to the next step!

10 : (Optional Step) ADDITIONAL GARMENT PRESS

It is possible to enhance the durability of the finished garment, and give a matte finish to the artwork by re-pressing the garment after the initial application. Different pressing papers or films can give different finishes, with one of our favourites being Thermal Buttress Paper.

- Wait for the the garment to completely cool down from the initital DTF transfer application. (with the DTF Film now peeled and removed).

- Return the garment to the heat press.

- Cover the garment/design with some thermal buttress paper.

- Repress the garment for an additional 10 seconds.

- Your Garment is now ready!

By following these steps, you can achieve professional-quality DTF prints with your Craft Express DTF Printer. Happy Printing!

If you have any questions or inquiries about any of our equipment or products, please feel free to reach out to us.

The team at Nova Chrome UK are here to assist you and provide any information you may need. Your satisfaction is our priority, and we’re ready to help in any way we can!

The OTTER PRO M30 DTF Printer

Supplied with our DTF printer kit are:

✅ 2.5L of OTTER PRO DTF ink (500ml of CMYKW).

✅ Roll of DTF Film (30cm x 100m, cold / hot peel).

✅ 1kg of Hot Melt Powder.

SHOP DTF

-

Otter Pro A4 DTF Film – Pk. 100

SKU: 4151 £16.00 Ex vat. £19.20 Inc vat. Add to basket -

Otter Pro A3 DTF Film – Pack 100

SKU: 4152 £29.00 Ex vat. £34.80 Inc vat. Add to basket -

Otter Pro DTF Film – Roll 30cm x 100m

SKU: 4153 £42.00 Ex vat. £50.40 Inc vat. Add to basket -

DTF Melt Powder – 1kg Bag

SKU: 4154 £25.00 Ex vat. £30.00 Inc vat. Add to basket -

DTF Ink 500ml – Black

SKU: 4155 £24.50 Ex vat. £29.40 Inc vat. Add to basket -

DTF Ink 500ml – Cyan

SKU: 4156 £24.50 Ex vat. £29.40 Inc vat. Add to basket -

DTF Ink 500ml – Magenta

SKU: 4157 £24.50 Ex vat. £29.40 Inc vat. Add to basket -

DTF Ink 500ml – Yellow

SKU: 4158 £24.50 Ex vat. £29.40 Inc vat. Add to basket -

DTF Ink 500ml – White

SKU: 4159 £29.00 Ex vat. £34.80 Inc vat. Add to basket -

iSmart Oven (40ltr) – Each

SKU: 3056 £245.00 Ex vat. £294.00 Inc vat. Add to basket -

A4 DTF Film Glow In The Dark – Pk. 10

SKU: 4160 £4.50 Ex vat. £5.40 Inc vat. Add to basket -

A4 DTF Film – Gold – Pk. 10

SKU: 4161 £4.50 Ex vat. £5.40 Inc vat. Add to basket